With the booming development of humanoid robots in various industries, Gaoke Plastics empowers with innovative materials, meeting the structural requirements of lightweight and high-strength while pursuing the ultimate performance of appearance.

For application scenarios such as humanoid robots and robotic dogs

High tech plasticization uses PPS, PA, LCP, PC/ABS, PPO and other core materials to provide flexible and efficient solutions. These materials can maintain excellent performance in complex environments, meeting the deep exploration of material applications and helping the robotics industry innovate and upgrade.

Key component material solution:

Joint bearings and gears

Material Science: PPS GK1140G A3-A6 W3-W5

Features: High rigidity, wear resistance, mechanical strength close to aluminum alloy, while achieving weight reduction.

Application: Ideal for high load moving parts such as joint bearings and gears, supporting flexible movement of robots.

Bracket and shell

Material Science: PPS GK1140G A3-A6 W3-W5

Features: Low shrinkage rate, dimensional stability.

Application: Suitable for spinal, upper arm, and lower leg support components of robots, reducing deformation.

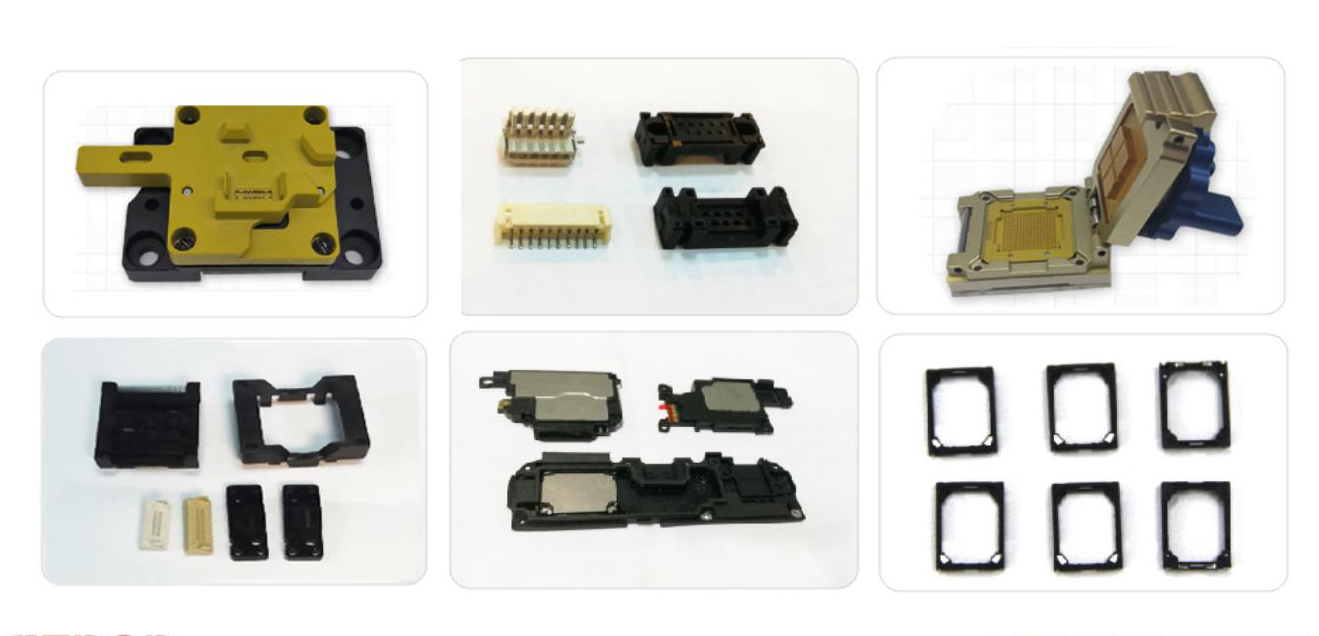

Motor insulation skeleton and connector

Material Science: PPS GK1140G A3-A6 W3-W5

Characteristics: High temperature resistance, electrical insulation performance.

Application: Ensure stable operation of electrical components such as motors and sensors in high-temperature environments.

3D printed components

Material Science: PA 66GK 330G30

Characteristics: High mechanical strength, good toughness, and wear resistance.

Application: Widely used in 3D printing of humanoid robot components, such as Poppy robots.

Sliding and wear-resistant components

Material Science: PA 66GK 330G30

Characteristics: Wear resistance, chemical stability.

Application: Manufacturing gears, bearings, and sliding parts for robots to reduce wear and improve lifespan.

High frequency signal transmission components

Material Science: LCP GK 1150G G30

Characteristics: Outstanding performance in high-frequency signal transmission and micro motor fields.

Application: Suitable for situations that require high-precision and high-frequency operation.

Shell and structural components

Material: PC/ABS (GK1100GA) alloy

Characteristics: Excellent heat resistance and processing fluidity.

Application: such as SoftBank's NAO robot, used for manufacturing shells and structural components.

Impact resistant components

Material Science: PC/ABS(GK1100GA)

Characteristic: Good impact resistance.

Application: Suitable for components that need to withstand external impact.

Potential application exploration:

PPO GK 830G10 may be used to make battery casings or certain internal structural components in humanoid robots due to its heat resistance, acid and alkali resistance, and corrosion resistance. Although there are currently few application cases, its potential needs to be further explored.

look into the future

Gaoke Plastics aspires to become a "leader in customized high-temperature modified plastics in China", always customer-centric, adhering to the core concept of "stability is the key", committed to providing cost-effective products and personalized material solutions, meeting market demand, and continuously creating value for customers.

[Disclaimer] The content and image materials of the article are sourced from the internet. Gaoke Plastics maintains neutrality in the statements and judgments made in the text, and does not provide any express or implied warranties regarding the reliability or completeness of the content contained therein. The purpose of outputting an article is to convey more information and share, provide industry communication, and does not imply agreement with its views or confirmation of its authenticity, nor does it constitute any other suggestions. If there are errors in the source of the material or infringement of your legitimate rights and interests, you can contact us by email or phone and delete it in a timely manner.