The engineering plastic solution of Gaoke Plasticization integrates three high-performance materials: PBT, PPS, and PEI, designed specifically for electronic and electrical component applications.

PBT: It has excellent chemical resistance and electrical properties, as well as excellent mechanical properties.

PPS: It exhibits excellent surface effects and high-precision size control, with equally outstanding mechanical properties and good epoxy resin adhesion.

PEI: Excellent flame retardancy, outstanding mechanical properties, and easy molding and processing.

Product characteristics

Excellent mechanical strength ensures long-term stable operation of electronic and electrical components in various application environments.

Stable dimensional accuracy meets the precise size requirements of capacitors.

Excellent electrical characteristics ensure high-performance performance of components.

Good bonding performance, easy to use in combination with electronic components or substrates.

Good fluidity, excellent flame retardant performance, easy molding, improving the production efficiency of electronic and electrical components.

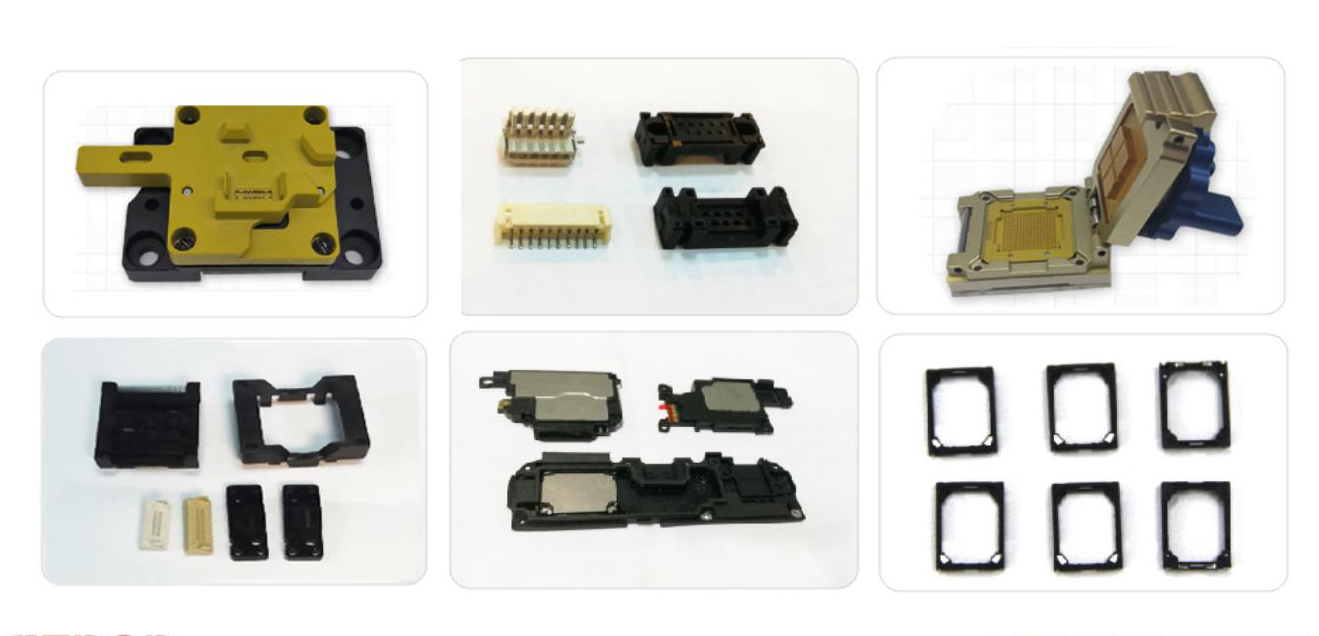

Typical applications

This engineering plastic solution is widely used in various industries such as electronics and electrical, household appliances, automotive electronics, consumer electronics, and new energy vehicles, especially in capacitor manufacturing, demonstrating excellent performance and adaptability

Specific specifications

model

characteristic

PBT GK430-301G20

PBT, 20% fiberglass reinforcement, environmentally friendly flame retardant, excellent chemical resistance and electrical performance, outstanding mechanical performance.

PPS GK430G-301G50

PPS、 50% fiberglass+mineral reinforcement, excellent surface effect and dimensional accuracy, excellent mechanical properties, good epoxy resin adhesion.

PEI GK430G-301G40

PEI、 40% fiberglass reinforcement, flame retardant, excellent mechanical properties, and easy molding.