Thermal stability and flame retardancy

Hot deformation temperature>260 ℃, continuously withstand high temperature environment of 150 ℃

Through UL94 V-0 highest flame retardant certification, providing intrinsic safety protection

Maintain material integrity in extreme temperature scenarios to ensure the safety of core components such as battery packs

Chemical corrosion resistance

Excellent medium resistance, able to resist chemical corrosion from fuel, coolant, battery electrolyte, etc

• Maintain long-term stability under complex working conditions and extend the service life of key components

Mechanical strength and creep resistance

• Maintain rigidity at high temperatures (>260 ℃ without deformation), with superior creep resistance compared to similar products

Maintain structural stability in high load scenarios and adapt to the design requirements of precision connectors

Reduce density by 40% compared to metal, achieving a breakthrough in lightweight design

Electrical performance stability

The dielectric constant/loss factor remains stable over a wide temperature range of -40 ℃ to 200 ℃

Excellent arc resistance performance (CTI>600V) ensures the reliability of signal transmission in high-voltage electrical systems

Processing and Cost Advantages

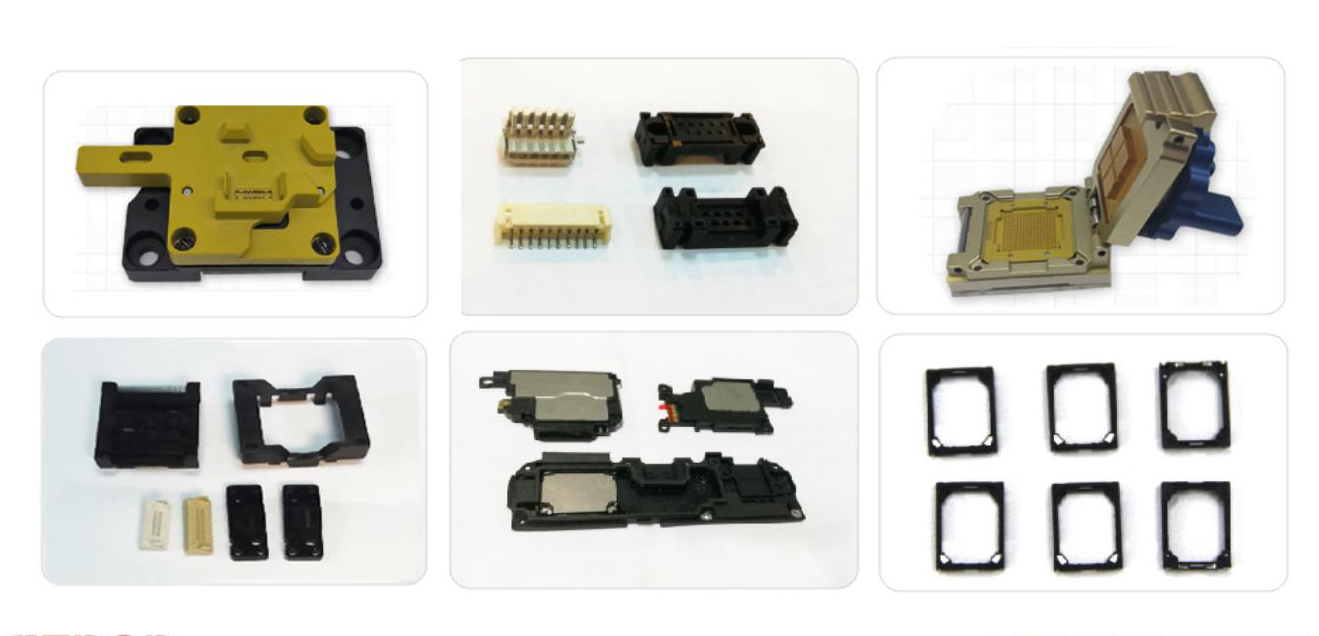

Low shrinkage rate (<0.3%)+high fluidity, supporting thin-walled precision injection molding

Processing accuracy of ± 0.02mm, suitable for automated production needs

Compared to metal solutions, it reduces system costs by 30% and has outstanding cost-effectiveness

Core advantages:

High temperature tolerance | Chemical defense | Precision molding | Thermal stability | Lightweight design